Industrial-Grade Sandblasting Room/Sand Blasting Cabinet/Sandblasting Booth for Metal Cleaning with Dust Collection

Category:

Sand Blasting Room

- Description

-

Key attributes

Industry-specific attributes

Other attributes

Lead time

Product descriptions from the supplier

Product descriptions from the supplier

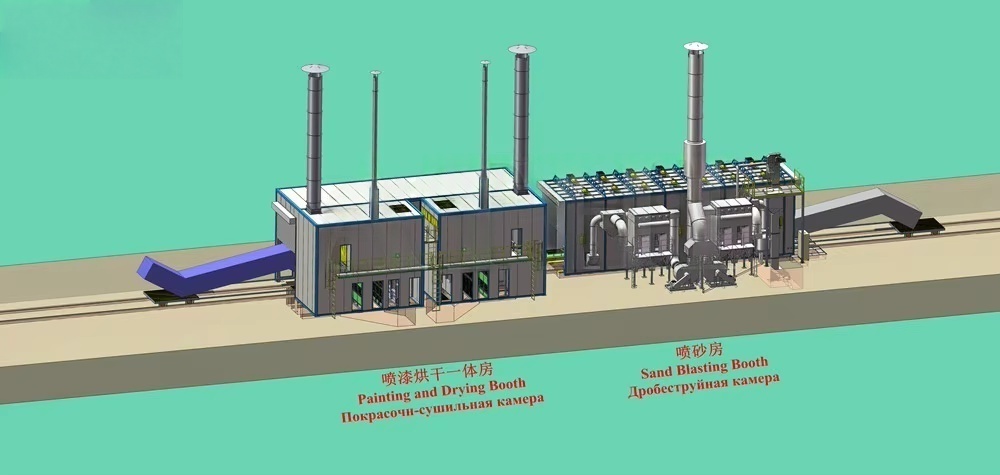

Shot Blasting Booth / Sand Blasting Room

Guangdong Zhongshan Quancheng boasts extensive expertise in manufacturing sandblasting rooms, specializing in customizing solutions to the most suitable dimensions based on clients’ requirements. Equipped with a trolley system, our sandblasting rooms efficiently handle large and irregular workpieces, ensuring comprehensive surface treatment. The integrated dust removal and abrasive recycling systems not only comply with environmental standards but also enable reutilization of steel sand, significantly reducing production costs.Our fully automatic recycling sandblasting rooms are designed according to product processing workflows and material characteristics, ideal for surface oxidation removal, rust elimination, strengthening, and enhancing coating adhesion on large castings, forgings, welded steel structures, engineering machinery, industrial boilers, chemical machinery, shipbuilding components, and more.

Whether for heavy-duty industrial applications or specialized material treatment, our sandblasting rooms combine technical innovation with practical efficiency to meet diverse production needs.

Technical Parameter

Details Images

OEM/ODM

We are committed to maintaining our position as the pioneers of our industry.With our own facilities, we can work on your OEM/ODM

projectsBlasting room chamber

Each Airblast blast room is meticulously custom-engineered to precisely align with unique operational requirements.

Automatic

Efficiently reclaim abrasives across the entire floor surface without any blind spots, ensuring timely recycling and thorough

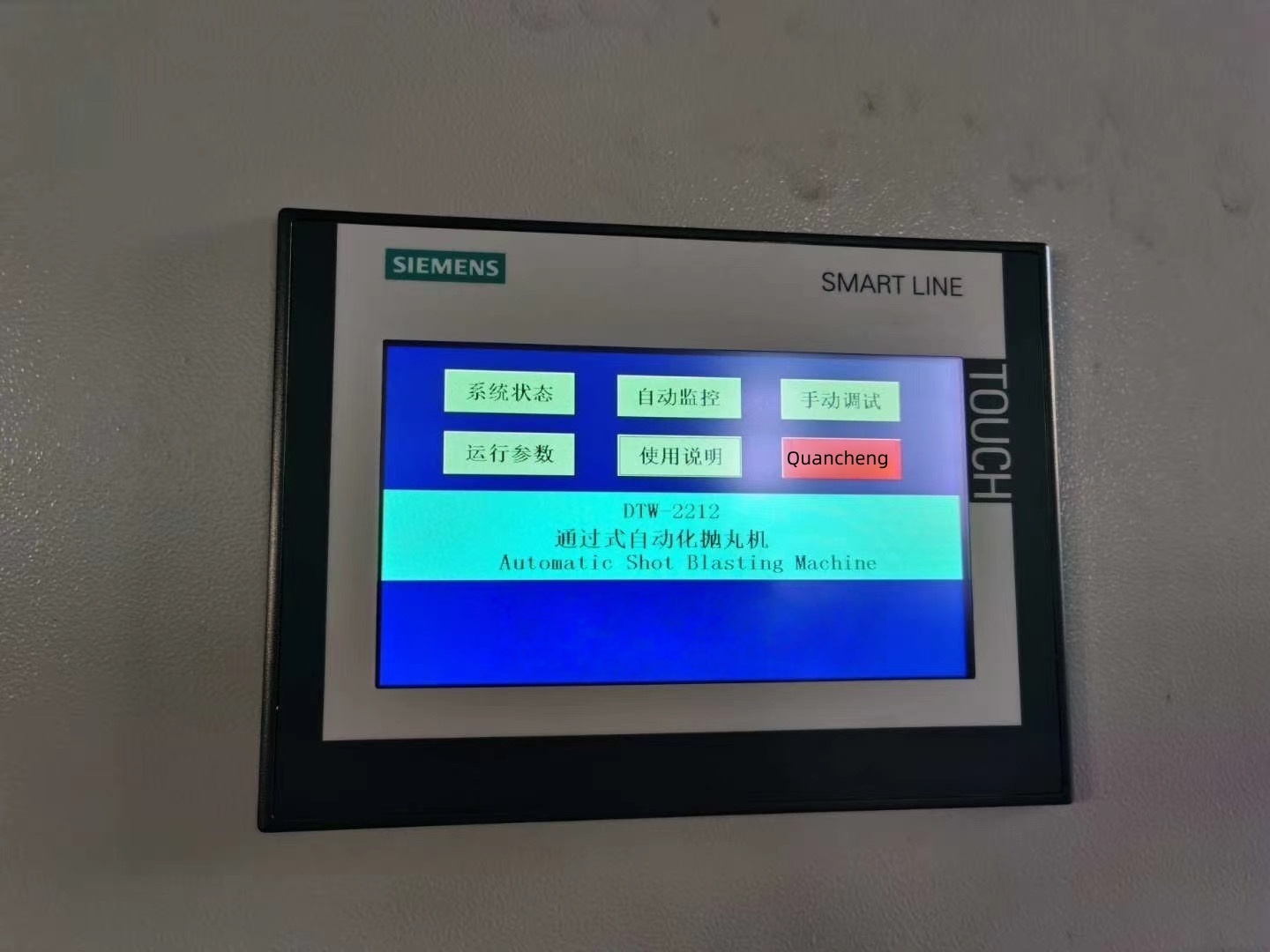

cleaning for reuse.Electric control system

The blasting turbines, maintenance door, abrasive controller, and abrasive circulation system are outfitted with an electric

interlock and self-locking system. This setup ensures foolproof equipment operation while prioritizing operator safety,

eliminating risks and guaranteeing seamless workflow.

High dust removal effect

The dust removal system integrates a high-efficiency ducting network with a filter cartridge dust collector, achieving emission

standards below 80g/m³. Powered by a 30kW fan, it delivers a robust ventilation capacity of 26,000m³/h, ensuring effective dust

extraction and a clean operational environment.Customizable trolley system

The trolley boasts a 10T load-bearing capacity, with the rail system spanning 35 meters in total length. To prevent projectile

wheel jams, a polyurethane scraper is installed ahead of each wheel, efficiently sweeping away scattered abrasives from the track

for smooth, uninterrupted operation.

Structural characteristics:

Shot blasting system

The shot blasting system is equipped with 1 set sand blasting pot, 1-2 guns. We fully take into account the operation convenience of the workers, specifically increased the shot blasting chamber operating space, set lighting system and platform, so that workers can operate convenient, effective and comprehensive on piece parts for shot-peening.

This machine equipped with shot peening special protective mask, greatly improving the working environment, and protect the health of operating workers.Shot distributing system

This machine adopts the patented shot valve produced of our company; it can accumulate a certain time in blasting, through the manual control to provide the shot ball to the blasting device.Dust-removing system

This machine adopts Cartridge or bag type dust collector, is exhausted air produced during working. The dedusting efficiency is up to 99.6%, powder density is less than 100mg/m3,much stricter than the national standard.Electric control system

Set shot ball circulatory failure alarm function, if any parts of the system fails, the above components automatically stop running, to prevent the shot ball stuck and burning power device.Notice:

According to your requirements, the most suitable machines will be designed for your workpieces, please indicate the follwing details.

1. What kind of workpiece will you clean?

2. The workpiece size, length, width, height and weight of maximum workpiece.

3. How many workpieces do you want to clean per day?

Based on this detail information, the detailed technical proposals will be sent to you for reference.BLASTING SAMPLE

Shot Blasting Booth / Sand Blasting Room

1. Exceptional Versatility & User - Friendliness

With a broad range of applications, this shot blasting machine offers effortless installation and intuitive operation, making it accessible for various industries.

2. Unwavering Stability & Reliability

Benefiting from decades of technical refinement, our machines feature mature technologies and are crafted by highly skilled workers. This ensures remarkable stability and an incredibly low failure rate, minimizing downtime and maintenance costs.

3. Tailored Solutions

We understand that every customer has unique requirements. That’s why we offer fully customized services, ensuring our shot blasting machines perfectly meet your specific operational needs.

4. Aesthetically Pleasing Design

Thanks to our sophisticated manufacturing processes, our machines not only perform flawlessly but also showcase an exquisite appearance, combining functionality with visual appeal.

5. Factory - Direct Competitive Pricing

As a direct manufacturer, we eliminate middlemen, offering you top - quality shot blasting machines at highly competitive prices, providing excellent value for your investment.

6. Swift Delivery

Housed in large - scale production facilities, we have the capacity and efficiency to ensure prompt order fulfillment. Rest assured that your machine will be delivered in a timely manner, getting your operations up and running quickly.

7. Rigorous Quality Assurance

Our dedicated quality inspection department conducts stringent checks at every production stage. From raw materials to the final product, we leave no stone unturned in ensuring the highest quality standards are met.

8. World - Class Electrical Components

The electrical control system predominantly features internationally renowned brands, guaranteeing precise control, enhanced safety, and long - term reliability.

9. Extensive Experience

With over many years of production experience, we have honed our skills and expertise in shot blasting machine manufacturing. Our deep industry knowledge enables us to deliver superior - performing products.

10. Professional Design Team

Our in - house team of professional designers is committed to providing you with comprehensive support. From initial concept to final design, they work closely with you to optimize the machine for your specific applications.

11. CE - Certified Quality

Our machines are CE - certified, meeting strict safety, health, and environmental standards, assuring you of their top -tier quality.

ABOUT US

1. Covers an area of 52106 square meters, including a building area of 34120 square meters.

2. The company has strong strength, with excellenteuipment, instruments, processes, and testing tchnology.

3. Strong R&D and technical team. Technical personnel account for 25% of the total number of employees.

4. Typical Customers: Midea, GREE, Panasonic, Macro, Vanward, XCMG Construction Machinery.

5. Quick oversea installation service & Quick response far after-sales & Quick spare parts delivery.

FACTORY SHOW

The company has accumulated rich experience in engineering management, as well as the design, manufacturing, and installation of complete sets of equipment for shot blasting and painting.

PRODUCTION PROCESS

A professional enterprise specializing in metal surface treatment, including the

design, production, installation, commissioning, and after-sales service of shot

blasting cleaning equipment, coating machinery equipment, and pressure vessels

OUR EXHIBITION

OUR CERTIFICATE

We assure you with our professional skill, competitive price and superior quality.

FAQ

What kind of installation support do you offer?

We've got you covered! For our standard shot blasting machines, we provide convenient remote - guided installation. This means you can get your machine up and running smoothly with our experts' guidance from anywhere in the world. If you opt for our non - standard equipment, we'll send 1 - 2 highly experienced engineers directly to your factory. They'll be on - site to guide the entire installation and assembly process, ensuring everything is set up perfectly to meet your unique requirements.

Do you supply abrasives for shot blasting machines?

Absolutely! We're not just about machines. We're your one - stop shop for all things related to shot blasting. We offer a wide range of high - quality metal abrasives, including steel shot, steel sand, wire - cut steel shot, and stainless steel shot. These abrasives are carefully selected to ensure efficient surface cleaning and excellent anti - corrosion results, helping you achieve the best performance from your shot blasting machine.

How long does delivery take?

We understand that time is money in your business. For standard shot blasting machines, you can expect delivery within 7 - 20 workdays. Non - standard models usually take 20 - 60 workdays, while shot peening machines are delivered within 30 - 60 workdays. Rest assured, we'll always do our best to meet your deadlines. The exact delivery time depends on the order quantity and machine model, but we'll keep you informed every step of the way.

What exactly does a shot blasting machine do?

A shot blasting machine is a game - changer for metal processing! It's a powerful tool that can clean, strengthen (also known as shot peening), and polish metal surfaces. Whether you're in the aerospace, automotive, construction, foundry, shipbuilding, rail, or countless other metal - using industries, our shot blasting machines can help you improve the quality and durability of your metal products, giving you a competitive edge in the market.

What pre - sales and after - sales services do you provide?

Our commitment to you doesn't end with the sale. Before you make a decision, our pre - sales team is here to answer all your questions, provide product samples, offer customized technical solutions, and give you accurate quotations. After your purchase, our after - sales support is top - notch. We offer a 24 - hour response service, so you can reach us anytime if you have an issue. Our engineers are available for online guidance, and if needed, they can come to your factory for on - site installation. We also provide comprehensive training on how to install and use the product properly, ensuring you get the most out of your investment in our shot blasting machines.

RELATED PRODUCTS

Get a Free Quote

Our representative will contact you soon.