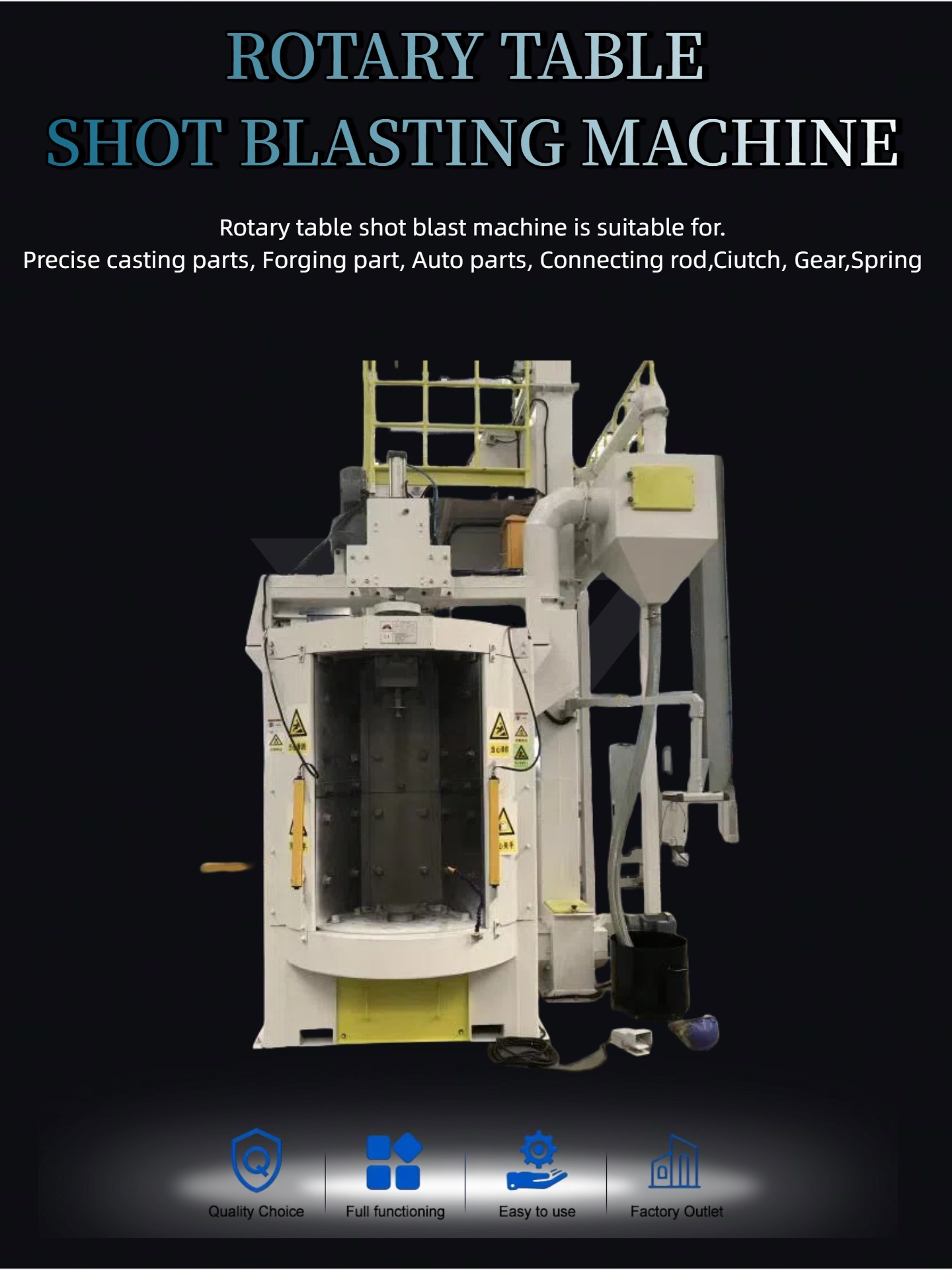

Q35 Series Rotary Table Shot Blasting Machine Gear/Brake Pad Cleaner with Engine Motor Gearbox Core Components for Deflashing

Category:

Rotary Table Shot Blasting Machine

- Description

-

Packaging and delivery

Key attributes

Lead time

Product Description

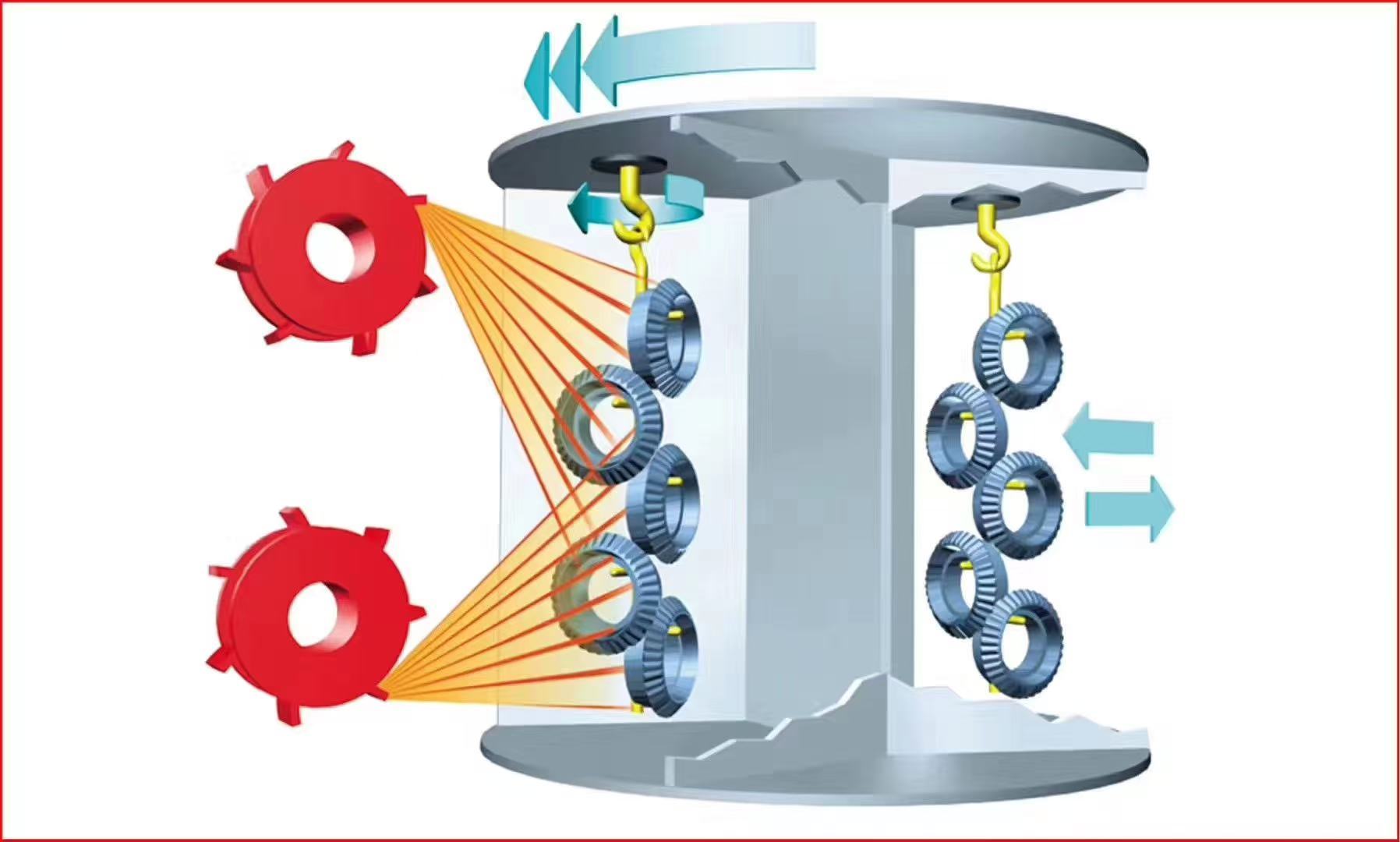

The rotary table shot blasting machine uses a rotary table as the workpiece carrying device. According to the diameter of the rotary table, it can be divided into φ1200 mm, φ1600 mm, φ1800 mm, φ2500 mm, etc. Some of these cleaning machines are equipped with one shot blasting machine, while others are equipped with two or more. Some operate continuously, while others operate intermittently, depending on the specific requirements. The working principle is as follows: Place the workpiece on the rotary table (with a certain distance between the workpieces to avoid contact and collision), and the rotary table brings the workpiece into the blasting area for shot blasting cleaning. When it reaches the unloading position, the workpiece can be removed. Therefore, this type is most suitable for workpieces that do not need to be cleaned on one side; otherwise, the workpiece should be flipped over for another round of cleaning. However, the rotary table hook-type shot blasting machine from Zhongshan Quancheng not only has a rotary table but also a hook, which has a rotating function. Therefore, it is suitable for surface treatment of various workpieces with high requirements

Product Features

Highlight advantages

It adopts a full manganese steel body and full manganese steel guard plate, with a service life of 20 years. Adopt an advanced Venturi wet dust removal system; Adopt a two-stage separation system for crushed pellets. Equipped with high-performance ABB motors and CNC-machined shot blasting wheels made of die steel; Adopt a steel shot flow automatic control system; Adopt an automatic turntable system; Magnetic separation system + lateral spiral separation + air separation system;

Technical parameter

PRODUCT DETAILS

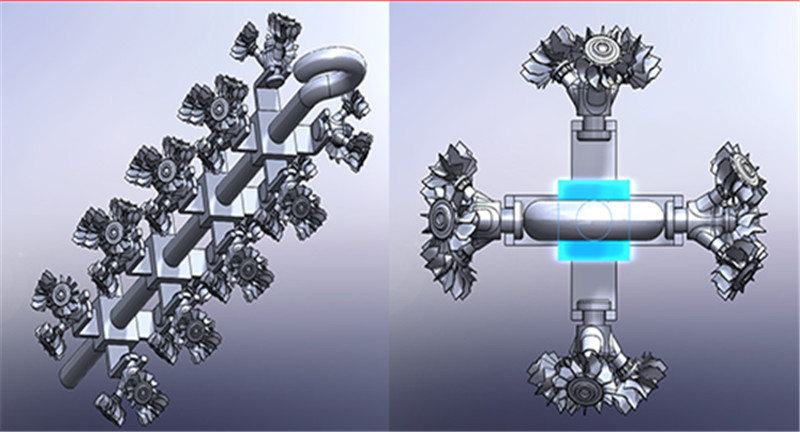

ABRASIVE RECYCLING SYSTEM

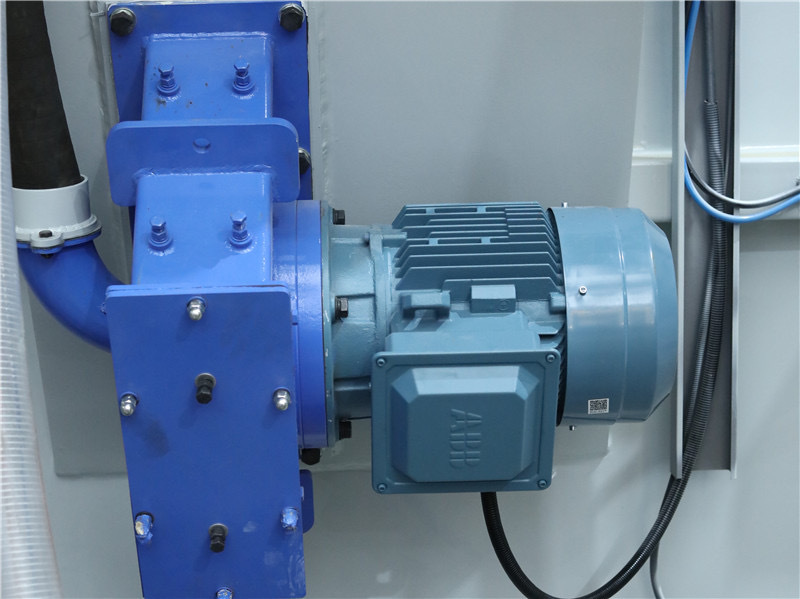

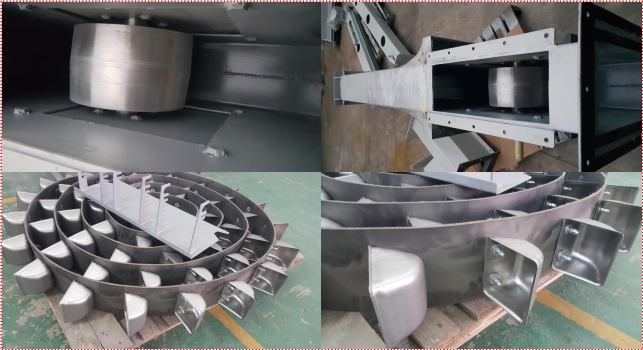

The motor of the shot blasting machine adopts ABB, with excellent and controllable manufacturing process, good sealing, excellent dynamic balance, and stable and reliable performance. The shell of the shot blasting machine is made of 10mm high-quality carbon steel plate through laser cutting, precise bending and welding. The shell is positioned and welded with special fixtures to ensure the parallelism of the two end faces and the concentricity of the holes of the shot blasting machine shell.

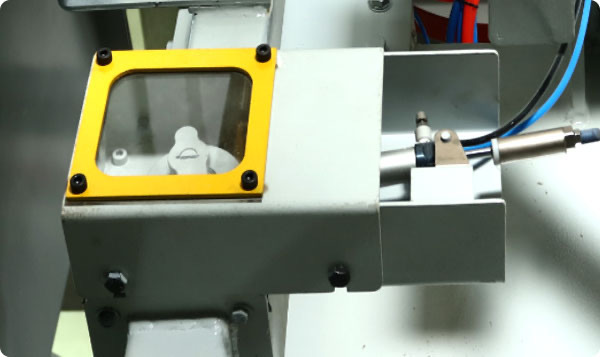

Flow control valve

Semi-automatic flow control system, used to control the flow of shot into the shot blasting machine, by manually adjusting the flow of steel shot. The fully sealed structure design is equipped with a lockable inspection opening and two bearings. At the top of each flow valve, there is a manual shut-off valve installed. When maintenance of the flow valve is required, it can be closed to stop the shot flowing down from the hopper, facilitating maintenance.

Shot blasting chamber body

Both sides of the rotating turntable are equipped with several layers of urethane rubber sealing devices, which can effectively prevent steel shot from splashing out of the machine through the gaps in the rotating wall.

The main turntable drive mechanism is located at the top of the shot blasting chamber, driven by a 1.5kw reduction motor to rotate at 180° intervals. Two small turntables are respectively located at the 180° position, driven by a cylinder to rotate through the reduction gear via gear meshing, thereby driving the fixture to rotate 360°.hoist

The elevator is used to lift the shot recovered by the screw conveyor to the separator and the storage bin. The hoist is precisely welded from steel plates and can be disassembled in sections. It is equipped with maintenance and inspection windows, making it easy to repair and inspect.

Rotary table system

The main turntable drive mechanism is located at the top of the shot blasting chamber, driven by a 1.5kw reduction motor to rotate at 180° intervals. Two small turntables are respectively located at the 180° position, driven by a cylinder to rotate through the reduction gear via gear meshing, thereby driving the fixture to rotate 360°.

Electric Control System

Adopt Siemens PLC and touch screen Use Delta or BEST frequency converters. Adopt a shot blasting time controller Use a flow detection ammeter.

Rotary Tableshot Blasting Machine

1. Exceptional Versatility & User - Friendliness

With a broad range of applications, this shot blasting machine offers effortless installation and intuitive operation, making it accessible for various industries.

2. Unwavering Stability & Reliability

Benefiting from decades of technical refinement, our machines feature mature technologies and are crafted by highly skilled workers. This ensures remarkable stability and an incredibly low failure rate, minimizing downtime and maintenance costs.

3. Tailored Solutions

We understand that every customer has unique requirements. That’s why we offer fully customized services, ensuring our shot blasting machines perfectly meet your specific operational needs.

4. Aesthetically Pleasing Design

Thanks to our sophisticated manufacturing processes, our machines not only perform flawlessly but also showcase an exquisite appearance, combining functionality with visual appeal.

5. Factory - Direct Competitive Pricing

As a direct manufacturer, we eliminate middlemen, offering you top - quality shot blasting machines at highly competitive prices, providing excellent value for your investment.

6. Swift Delivery

Housed in large - scale production facilities, we have the capacity and efficiency to ensure prompt order fulfillment. Rest assured that your machine will be delivered in a timely manner, getting your operations up and running quickly.

7. Rigorous Quality Assurance

Our dedicated quality inspection department conducts stringent checks at every production stage. From raw materials to the final product, we leave no stone unturned in ensuring the highest quality standards are met.

8. World - Class Electrical Components

The electrical control system predominantly features internationally renowned brands, guaranteeing precise control, enhanced safety, and long - term reliability.

9. Extensive Experience

With over many years of production experience, we have honed our skills and expertise in shot blasting machine manufacturing. Our deep industry knowledge enables us to deliver superior - performing products.

10. Professional Design Team

Our in - house team of professional designers is committed to providing you with comprehensive support. From initial concept to final design, they work closely with you to optimize the machine for your specific applications.

11. CE - Certified Quality

Our machines are CE - certified, meeting strict safety, health, and environmental standards, assuring you of their top -tier quality.

ABOUT US

1. Covers an area of 52106 square meters, including a building area of 34120 square meters.

2. The company has strong strength, with excellenteuipment, instruments, processes, and testing tchnology.

3. Strong R&D and technical team. Technical personnel account for 25% of the total number of employees.

4. Typical Customers: Midea, GREE, Panasonic, Macro, Vanward, XCMG Construction Machinery.

5. Quick oversea installation service & Quick response far after-sales & Quick spare parts delivery.

FACTORY SHOW

The company has accumulated rich experience in engineering management, as well as the design, manufacturing, and installation of complete sets of equipment for shot blasting and painting.

PRODUCTION PROCESS

A professional enterprise specializing in metal surface treatment, including the

design, production, installation, commissioning, and after-sales service of shot

blasting cleaning equipment, coating machinery equipment, and pressure vessels

OUR EXHIBITION

OUR CERTIFICATE

We assure you with our professional skill, competitive price and superior quality.

FAQ

What kind of installation support do you offer?

We've got you covered! For our standard shot blasting machines, we provide convenient remote - guided installation. This means you can get your machine up and running smoothly with our experts' guidance from anywhere in the world. If you opt for our non - standard equipment, we'll send 1 - 2 highly experienced engineers directly to your factory. They'll be on - site to guide the entire installation and assembly process, ensuring everything is set up perfectly to meet your unique requirements.

Do you supply abrasives for shot blasting machines?

Absolutely! We're not just about machines. We're your one - stop shop for all things related to shot blasting. We offer a wide range of high - quality metal abrasives, including steel shot, steel sand, wire - cut steel shot, and stainless steel shot. These abrasives are carefully selected to ensure efficient surface cleaning and excellent anti - corrosion results, helping you achieve the best performance from your shot blasting machine.

How long does delivery take?

We understand that time is money in your business. For standard shot blasting machines, you can expect delivery within 7 - 20 workdays. Non - standard models usually take 20 - 60 workdays, while shot peening machines are delivered within 30 - 60 workdays. Rest assured, we'll always do our best to meet your deadlines. The exact delivery time depends on the order quantity and machine model, but we'll keep you informed every step of the way.

What exactly does a shot blasting machine do?

A shot blasting machine is a game - changer for metal processing! It's a powerful tool that can clean, strengthen (also known as shot peening), and polish metal surfaces. Whether you're in the aerospace, automotive, construction, foundry, shipbuilding, rail, or countless other metal - using industries, our shot blasting machines can help you improve the quality and durability of your metal products, giving you a competitive edge in the market.

What pre - sales and after - sales services do you provide?

Our commitment to you doesn't end with the sale. Before you make a decision, our pre - sales team is here to answer all your questions, provide product samples, offer customized technical solutions, and give you accurate quotations. After your purchase, our after - sales support is top - notch. We offer a 24 - hour response service, so you can reach us anytime if you have an issue. Our engineers are available for online guidance, and if needed, they can come to your factory for on - site installation. We also provide comprehensive training on how to install and use the product properly, ensuring you get the most out of your investment in our shot blasting machines.

RELATED PRODUCTS

Get a Free Quote

Our representative will contact you soon.